Exceptional wedding rings in mokume gane combined with family gold

In the workshop of master goldsmith Markus Wiesner, a new pair of wedding rings is handmade using the Japanese mokume gane technique.

The special challenge: a pair of gold wedding rings Wedding rings from family property are incorporated into the Mokume Gane rings Tornillo rings.

Markus Wiesner is currently forging your Mokume Gane wedding rings - click on the picture to see more impressions from the workshop.

A small ingot must first be cast from the existing gold rings, which is then forged into a thin sheet and rolled out. This sheet of the original family gold is then welded together with the palladium and silver sheets to form a mokume gane ingot, from which the Tornillo wedding rings are then forged.

Documentation of wedding ring production with family gold

1) The bride and groom's family gold - here 2 pairs of wedding rings from the grandparents

Some of these family wedding rings should be incorporated into the rings. Wedding rings are very suitable for direct processing, as they produce a very homogeneous alloy when melted. Fine gold chains, for example, are less suitable for this, as they introduce a lot of unknown solder material due to the countless solder points between the links. Melts made from this material are usually blotchy, as the precious metal mixture is difficult to homogenize.

2) The melted and cast family gold is rolled. (Some more videos of melting and casting follow)

After melting and homogenizing the alloy, it is cast into a small ingot, which is then formed into a sheet by rolling and forging.

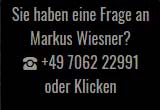

3) The rolled family gold next to the other sheets of Mokume Gane wedding rings

As can be clearly seen here, precious metal can take on very unattractive colors during processing. These are usually superficial oxides caused by heat and/or the rolling process. The long dark stripe in the family gold plate, for example, is such a discoloration. Pickling and sanding removes these superficial traces.

4) Cut sheet metal made from family gold - exceptionally beautiful color tone

The family gold sheet has now been stripped, sanded and cut to size. Now you can clearly see that the color of the family gold is much stronger than the 750 yellow gold that we use for the remaining layers of these extraordinary wedding rings. Not only a beautiful, warm shade, but also a good distinguishing feature. It is highly likely that this strip of precious metal can be easily distinguished from the other gold strips later on.

Below you can see all the sheets at a glance.

6) Fully sorted and stacked Mokume Gane bars

This is the entire stack of precious metal sheets, palladium, silver, yellow gold and family gold, which has been cut and sorted in order and fixed with some adhesive tape. The various precious metals are now welded together using a 10-hour diffusion welding process in the oven.

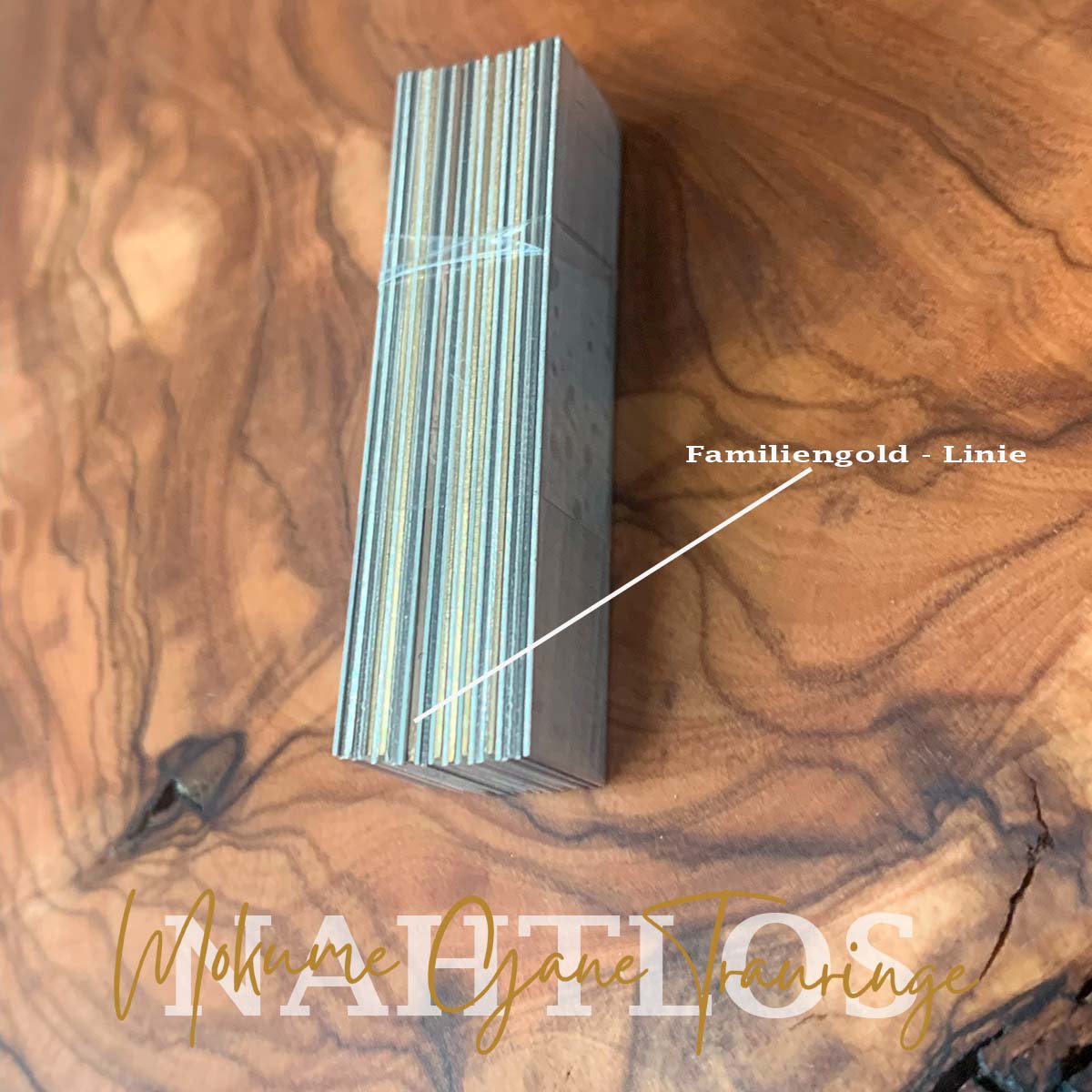

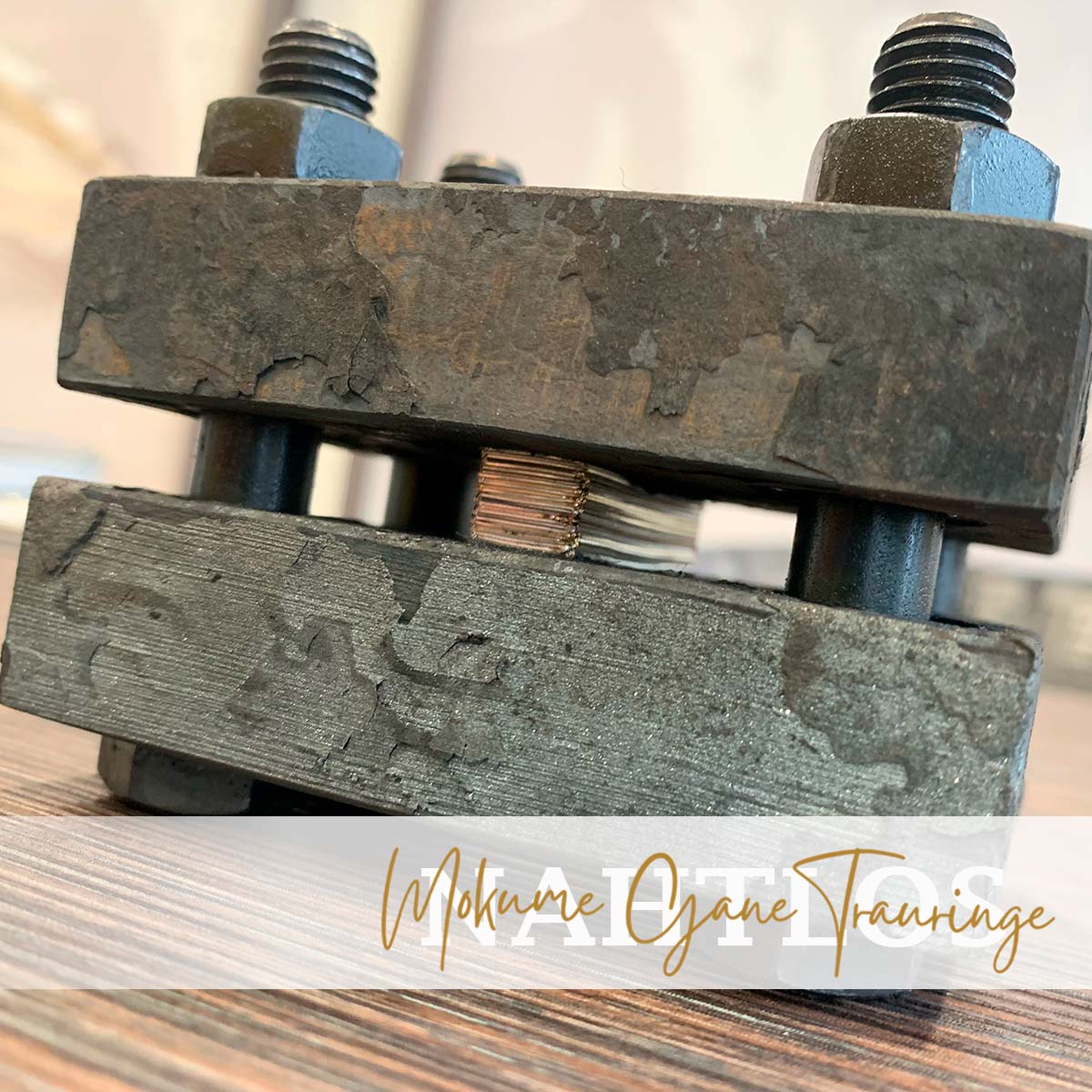

7) Mokume Gane layer block clamped in place

7) Mokume Gane layer block packed in the furnace

At around 800 degrees Celsius, the atoms at the interfaces become active and begin to mix. A layer of a new alloy about 1/10 of a millimeter thick is created. Between yellow gold and silver. Between yellow gold and palladium, between silver and palladium, and so on.

8) The layer block and clamping device are cold again. Soon the wedding ring production can continue.

The mokume gane material is now welded and cooled.

You can still clearly see the strip of family gold in the middle of the ingot. It is slightly darker and thicker.

The ash still comes from the filling material that surrounds the ingot during welding.

9) And here it is. The finished mokume gane ingot for the wedding rings

10) The mokume gane ingot is now rolled to length.

10) Torsion for the pattern design

11) Twisted strand rolled to square

12) Mokume Gane strand drilled, sawn and spliced

13) Mokume Gane rings further expanded

14) Mokume Gane rings forged round

15) The ends of the mokume gane strand were forged in

To ensure that the rings are nicely round on the inside and have no notches, the protrusions are forged from the outside inwards. Very beautiful and wild patterns are usually created in these places, which can hardly be guessed beforehand. The remaining part is milled off.

15) Rough round milling of the wedding rings

The remaining protrusions have now been milled off. In addition, the mokume gane rings have already received a rough rounding of the profile.

16) Rings have been reduced in size

At this stage, these Mokume Gane rings also show a hot pattern. depending on your taste, they are already ready to wear

17) And they are getting smaller and smaller

18) And a little smaller again

19) Now the rings become even wider

When you make them smaller, the material has to go somewhere. So it goes into the width. That means soon in the profile height. Then they are forged to the width. In order to achieve the desired width and thickness at the end, this growth in thickness and then in width must be taken into account beforehand when calculating the material. This also produces beautiful rings. Very rustic, but absolutely unique.

20)The wedding rings are now more finely polished

As the rings should not end up as rustic as above, they are now sanded flat and the sides are straightened.

21) Straightened sides of the mokume gane wedding rings

As you can see at this stage, at least on the larger ring, there are sometimes small nicks and cracks from the forming process. Of course, you don't want these in the finished rings. For this reason, the original material must be chosen to be sufficiently lush so that there is still enough room to straighten out such imperfections at the end. This is why about 2/3 of the original material ends up as shavings in the goldsmith's skin (leather cloth under the arebit place) and has to be recycled.

22) Hooray, the Mokume Gane rings are getting their profile

Slowly but surely, the shape, colors and patterns are coming closer to the selected design of the wedding rings. Now the glass bead surface and off we go to the engraver. The strip of family gold cannot be seen with this surface and in this exposure. A better picture will follow.